Professional China 18 Layer Pcb Fabrication - Rogers 3003 selective plating PCB for radar product – Pandawill

Professional China 18 Layer Pcb Fabrication - Rogers 3003 selective plating PCB for radar product – Pandawill Detail:

Product Details

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Layers | 2 layers |

| Board thickness | 0.29 MM |

| Material | Rogers 3003 Er:3.0 |

| Copper thickness | Selected plating, 0.5 OZ base copper(part remain 0.5OZ and part plated 1 OZ) |

| Surface Finish | Immersion silver |

| Packing | Anti-static bag |

| E-test | Flying probe or Fixture |

| Acceptance standard | IPC-A-600H Class 2 |

| Application | Telecom/Automotive |

Introduction

In order to meet increasing demands for Microwave & RF Printed Circuit Boards for our customers all around the world, we have increased our investment over the last few years so that we have become a world class manufacturer of PCBs using high frequency laminates.

These applications typically require laminates with specialized electrical, thermal, mechanical, or other performance characteristics that exceed those of traditional standard FR-4 materials. With our many years of experience with PTFE-based microwave laminate, we understand the high reliability and tight tolerance requirements of most applications.

PCB Material For RF PCB

Will all the different features of every RF PCB application, we have developed partnerships with the key material suppliers such as Rogers, Arlon, Nelco, and Taconic just to name a few. While many of the materials are very specialized, we do hold significant stock of product in our warehouse from Rogers (4003 & 4350 series) and Arlon. Not many companies are prepared to do that given the high cost of carrying inventory to be able to respond quickly.

High technology circuit boards fabricated with high frequency laminates can be difficult to design because of the sensitivity of the signals and the challenges with managing the thermal heat transfer in your application. The best high-frequency PCB materials have low thermal conductivity versus the standard FR-4 material used in standard PCBs.

RF and microwave signals are very sensitive to noise and have much tighter impedance tolerances than traditional digital circuit boards. By utilizing ground plans and using a generous bend radius on impedance controlled traces can help make the design perform in the most efficient manner.

Because wavelength of a circuit is frequency dependent and material dependent, PCB materials with higher dielectric constant (Dk) values can result in smaller PCBs as miniaturize circuit designs can be used for specific impedance and frequency ranges. Oftentimes high-Dk laminates (Dk of 6 or higher) are combined with lower cost FR-4 materials to create hybrid multilayer designs.

Understanding the coefficient of thermal expansion (CTE), dielectric constant, thermal coefficient, temperature coefficient of dielectric constant (TCDk), dissipation factor (Df) and even items like relative permittivity, and loss tangent of the PCB materials available will help the RF PCB designer create a robust design that will exceed the required expectations.

Wide Ranging Capabilities

In addition to standard Microwave/RF PCBs our capabilities using PTFE laminates also include:

Hybrid or Mixed Dielectric Boards (PTFE/FR-4 combinations)

Metal Backed and Metal Core PCBs

Cavity Boards (Mechanical and Laser Drilled)

Edge Plating

Constellations

Large Format PCBs

Blind/Buried and Laser Via’s

Soft Gold and ENEPIG Plating

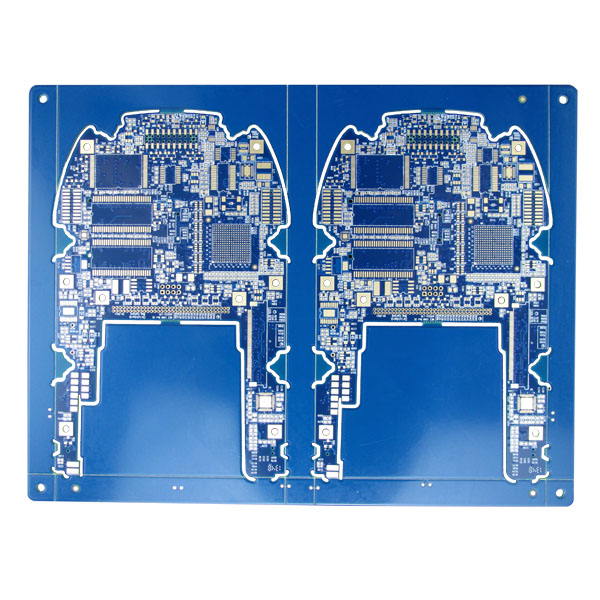

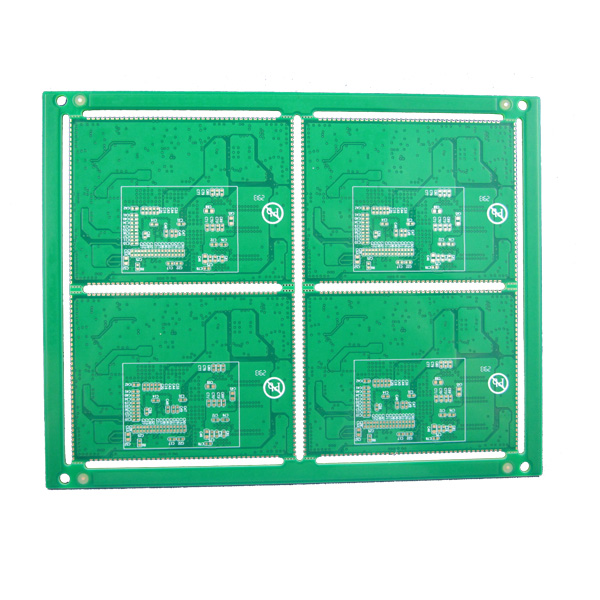

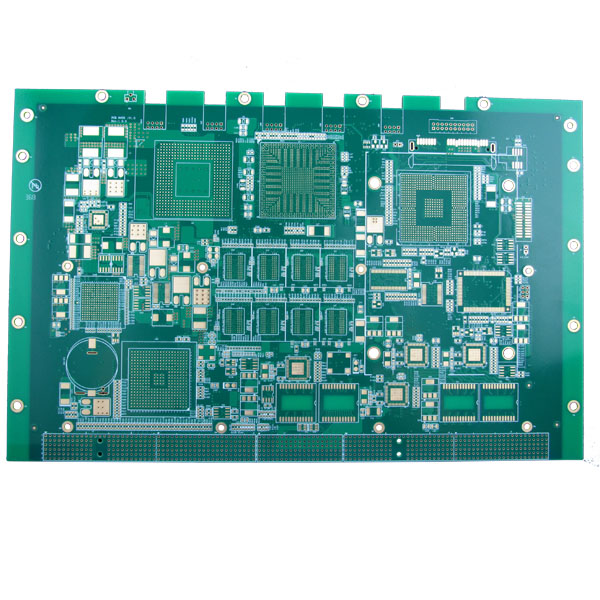

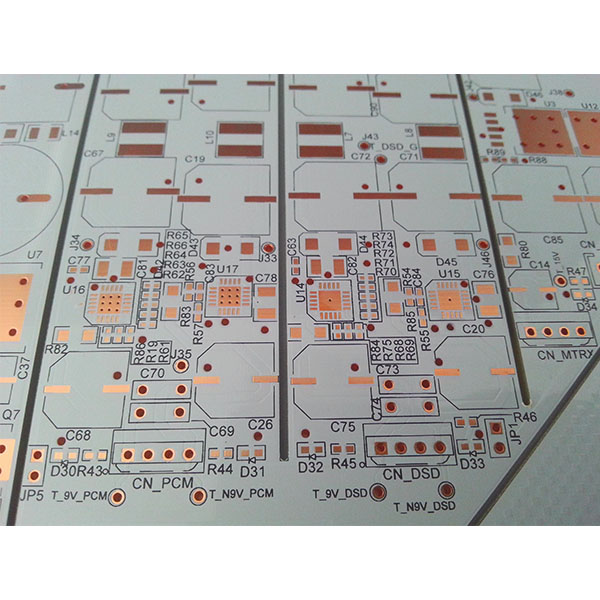

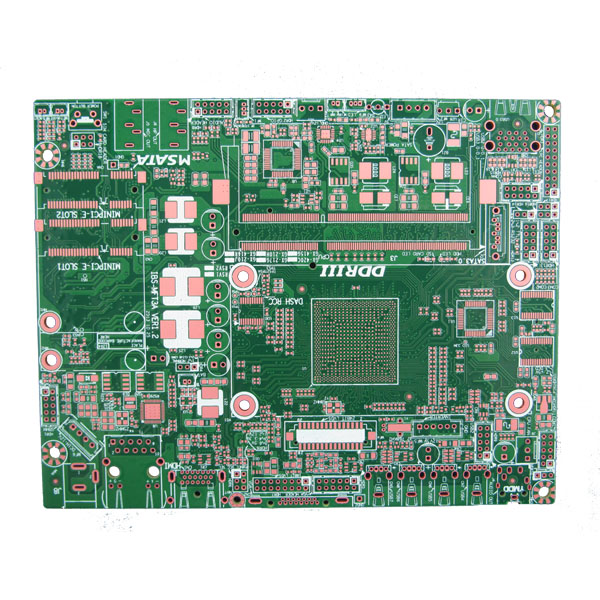

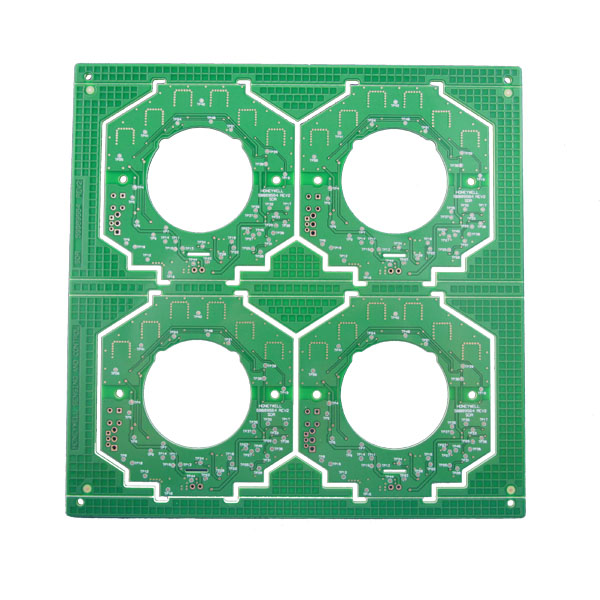

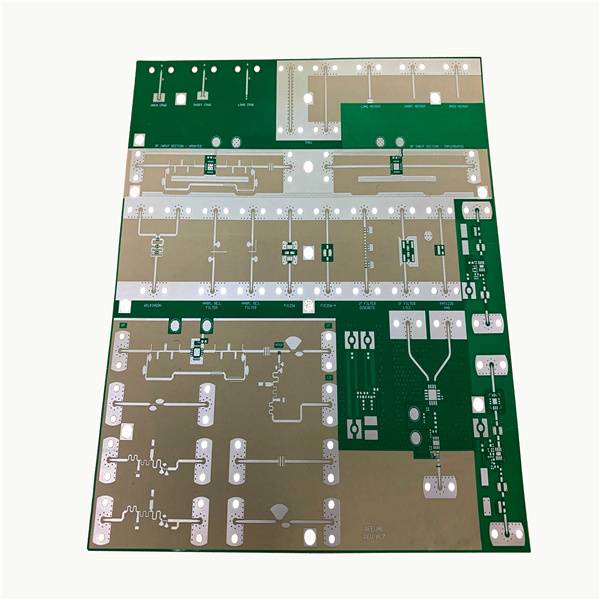

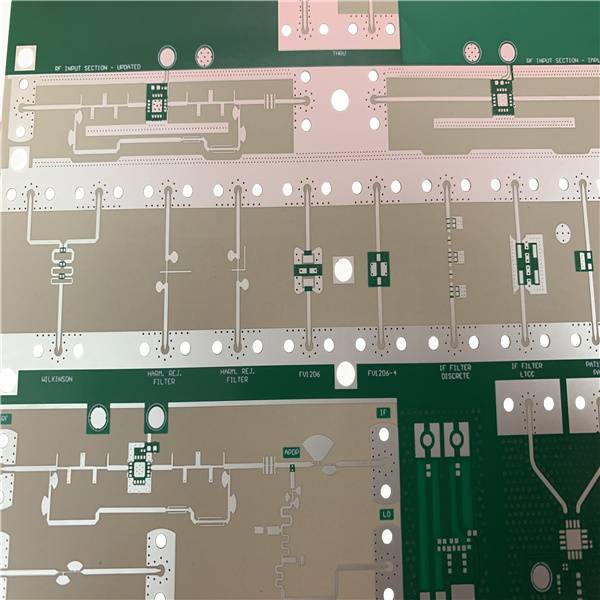

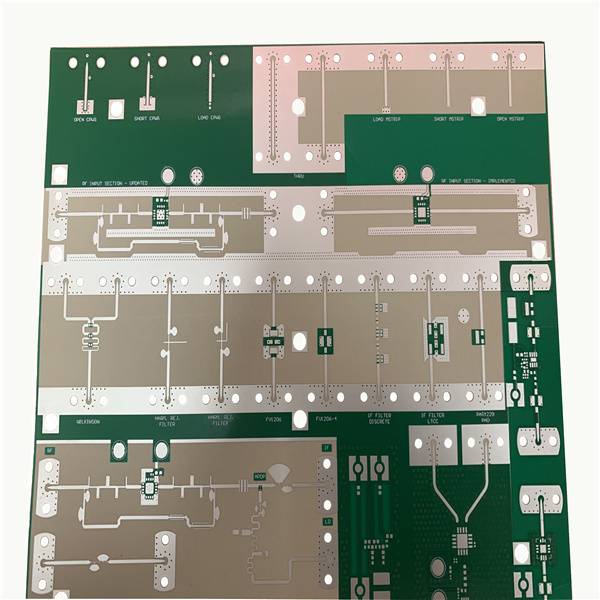

Product detail pictures:

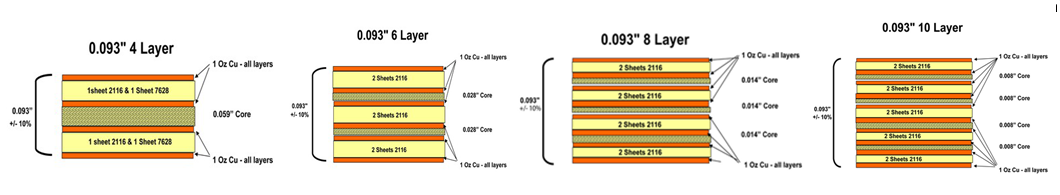

Related Product Guide:

We believe that prolonged time period partnership is really a result of top of the range, benefit added provider, prosperous knowledge and personal contact for Professional China 18 Layer Pcb Fabrication - Rogers 3003 selective plating PCB for radar product – Pandawill , The product will supply to all over the world, such as: Philippines, Rwanda, Lithuania, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!