In addition to all of the standard PCB specifications that we supply, Pandawill also offer a number of additional processes that either optimize the performance of your circuit boards in relation to their intended use, or assist with multi-stage assembly processes to reduce labor and improve throughput efficiency.

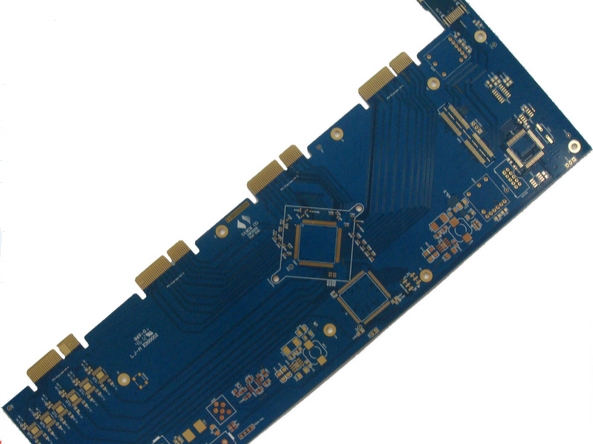

Selective ‘hard gold plating: Applications that require elevated levels of edge or surface connectivity with the use of gold fingers or connector pads.

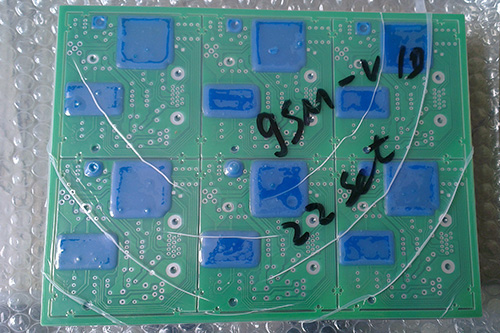

Peelable solder mask: Pandawill offer the best commercially available grade of peelable solder mask for use in multi-pass thermal assembly processes. The peelable resist layer is used to cover areas that are not to be soldered during the solder wave process. This flexible layer can then be subsequently removed easily to leave pads, holes and solderable areas perfect condition for secondary assembly processes and component/connector insertion.

Blind vias: For series manufacture,laser drilling is the only economic, but not the only technically possible solution. when prototyping, the most modern CNC (mechanical) drilling machine and special innovative tools are available to produce mechanically drilled holes of an equal quality and at least equal cost effectiveness.

Filled vias: There are several filled via options to match your requirement. Vias can be filled with either conductive metal paste for continuity, epoxy resin for use where the PCB forms an active barrier in intrinsically safe applications and copper filled to aid with temperature dissipation under components synonymous with the generation of localized heat on the board.

Carbon Print: Carbon is used for keyboard and LCD contacts and contact pins. The lacquer is based on carbon and can be easily applied to surfaces due to the large content of solids.

Controlled impedance: controlled impedance are mostly required in the microwave technology, broadcast, military and communications sectors. we only utilize certified materials with controlled dielectric constant (Dk) and loss tangent/dissipation factors (Df) and issue the appropriate test to match your application requirements.