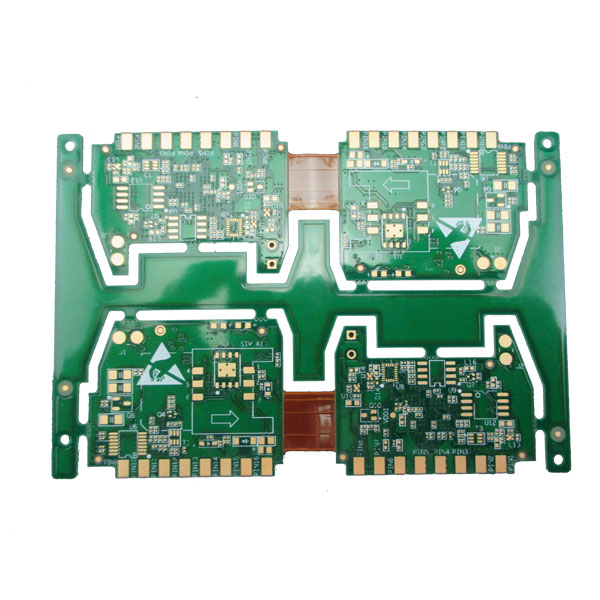

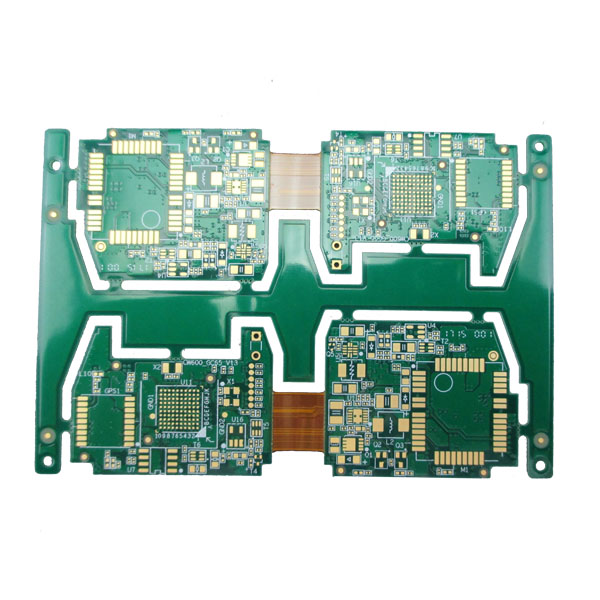

18 Years Factory Electronic Contract Manufacturing - 4 layer rigid flex circuit board for automotive – Pandawill

18 Years Factory Electronic Contract Manufacturing - 4 layer rigid flex circuit board for automotive – Pandawill Detail:

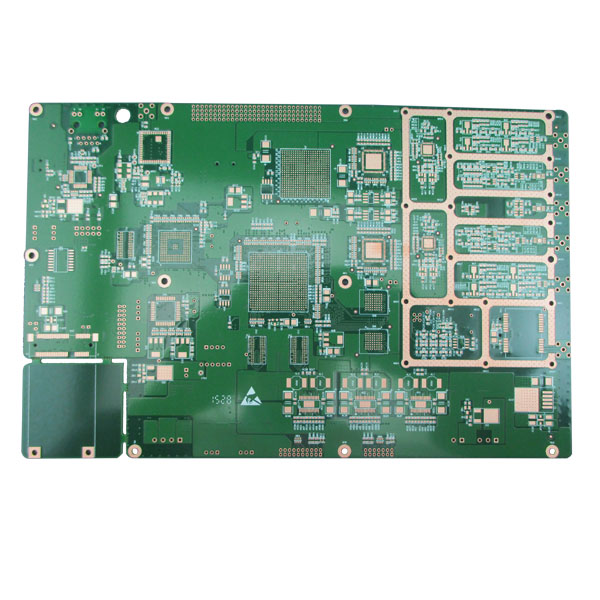

Product Details

| Layers | 4 layers rigid, 2 layers flex |

| Board thickness | 4 layers rigid, 2 layers flex |

| Material | Shengyi S1000-2 FR-4(TG≥170℃) + Polyimide |

| Copper thickness | 1 OZ(35um) |

| Surface Finish | (ENIG 3μm) Immersion gold |

| Min Hole(mm) | 0.22mm |

| Min Line Width(mm) | 0.15mm |

| Min Line Space(mm) | 0.18mm |

| Solder Mask | Green |

| Legend Color | White |

| Packing | Anti-static bag |

| E-test | Flying probe or Fixture |

| Acceptance standard | IPC-A-600H Class 2 |

| Application | Optics device |

Introduction

Rigid-flex PCB means hybrid systems, which combine the characteristics of rigid and flexible circuit substrates in one product. Whether in medical technology, sensors, mechatronics or in instrumentation, electronics squeezes ever more intelligence into ever smaller spaces, and the packing density increases to record levels again & again. Using flexible PCBs and rigid-flex printed circuit boards, whole new horizons open up for electronic engineers and designers.

Advantages of rigid-flex PCB

l Reduction of weight and volume

l Defined characteristics of the circuit systems on the circuit board (impedances and resistances)

l Reliability of the electrical connections due to reliable orientation and reliable contacts as well as savings on connectors and wiring

l Dynamically and mechanically robust

l Freedom to design in 3 dimensions

Materials

Flexible base material: Flexible base material consists of a foil made of flexible polyester or polyimide with tracks on one or both sides. PANDAWILL uses polyimide materials exclusively. Depending on the application, we may use Pyralux and Nikaflex made by DuPont and the glueless flexible laminates in the FeliosFlex series made by Panasonic.

Apart from the thickness of the polyimide, the materials mainly differ in their adhesive systems (glueless or on epoxy or acrylic basis) as well as in the copper quality. For comparatively static bending applications with a low number of bend cycles (for assembly or maintenance) ED (electro-deposited) material is adequate. For more dynamic, flexible applications RA (rolled annealed) materials must be used.

Materials are selected on the basis of the product and production specific requirements, and the datasheets of the materials used can be requested as required.

Adhesive systems: As a bonding agent between the flexible and the rigid materials, systems using adhesive on an epoxy or acrylic basis (which is still capable of reacting) are used. The options are as follows:

Composite film (polyimide film coated on both sides with adhesive)

Adhesive films (adhesive systems poured onto a paper base and covered with a protective film)

No-flow prepregs (glass mat/epoxy resin prepreg with very low resin flow)

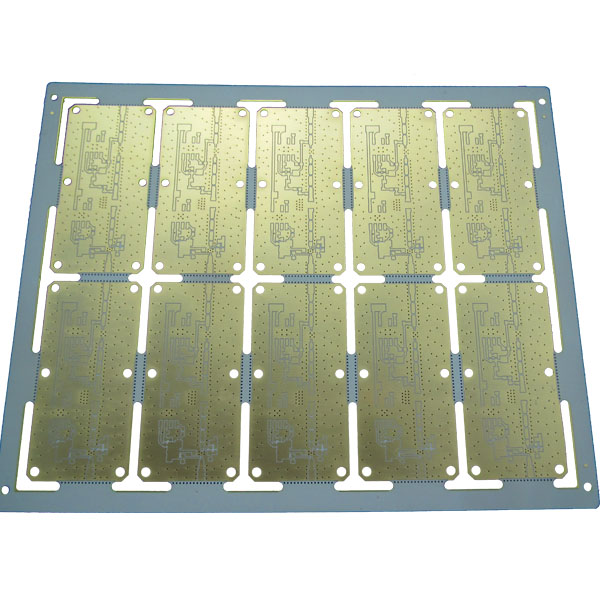

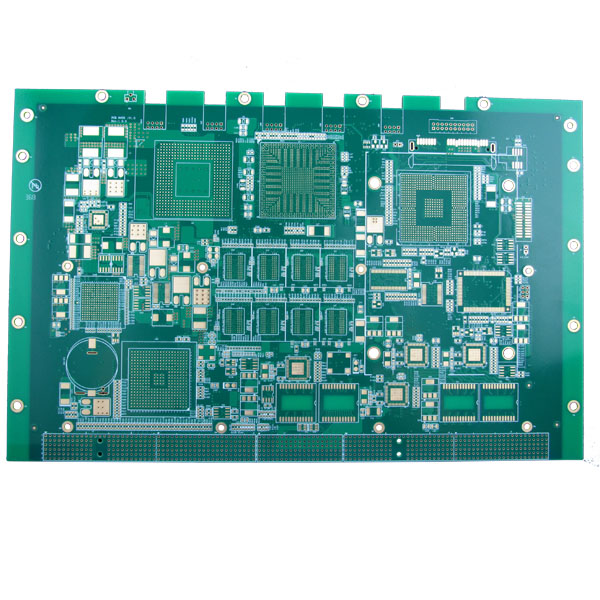

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict good quality manage, reasonable rate, superior assistance and close co-operation with shoppers, we have been devoted to supplying the very best price for our consumers for 18 Years Factory Electronic Contract Manufacturing - 4 layer rigid flex circuit board for automotive – Pandawill , The product will supply to all over the world, such as: Wellington, London, Iran, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly